-

Wheel Hub Bearings

Wheel Hub Bearings -

Wheel Hub Bearings

Wheel Hub BearingsDAC387436 DAC458045 Hub Deep Groove Ball Car Wheel Bearing

-

Spherical Bearings

Spherical BearingsFL204 FL205 FL206 Stainless Steel Pillow Block Bearing

-

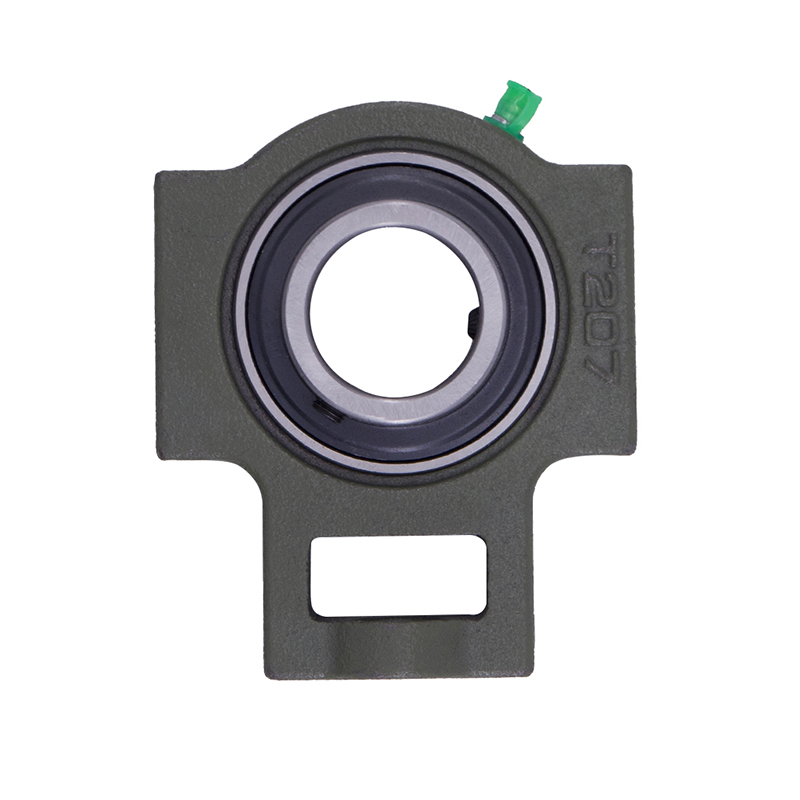

Spherical Bearings

Spherical BearingsT204 T207 UC204 High Speed Insert Pillow Block Bearing

-

Spherical Bearings

Spherical BearingsFC204 F210 Auto Wheels Bike Pillow Block Bearing

-

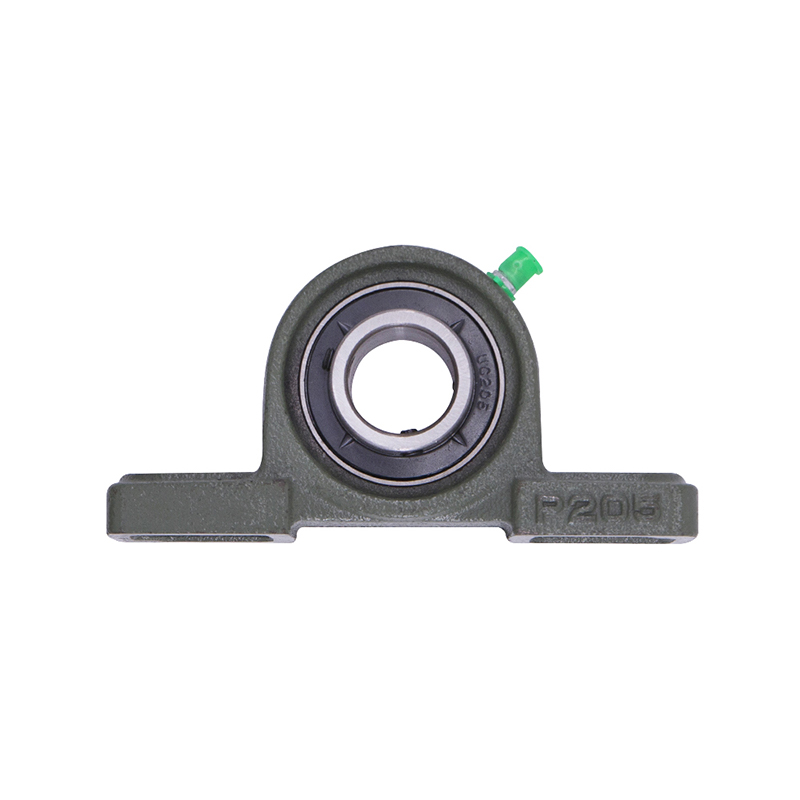

Spherical Bearings

Spherical BearingsP207 206 205 203 High Precision Wheel Pillow Block Bearing

-

Thrust Roller Bearings

Thrust Roller BearingsS51100 S51107 S51109 Car Wheel Plain Thrust Ball Bearing

-

Thrust Roller Bearings

Thrust Roller Bearings51110 51107 51104 51206 High Speed Plain Thrust Ball Bearing

Development of the bearing industry?

Company News-Bearings are important basic components of various mechanical equipment, and their accuracy, performance, lifespan, and reliability play a decisive role in the accuracy, performance, lifespan, and reliability of the host. In mechanical products, bearings belong to high-precision products, which not only require comprehensive support from various disciplines such as mathematics and physics, but also require services from materials science, heat treatment technology, precision machining, and measurement technology, CNC technology, effective numerical methods, and powerful computer technology. Therefore, bearings are also a product representing the country's scientific and technological strength.

After the outbreak of the 2008 international financial crisis, the country adopted an active fiscal policy of increasing infrastructure investment and driving economic development in response to the financial crisis. Benefiting from the development of related industries, bearing production and sales have rapidly expanded, profit levels have been improved, and industry development has significantly accelerated. According to the "Forecast of Production and Sales Demand and Analysis of Transformation and Upgrading in China's Bearing Manufacturing Industry" released by Forward Industry Research Institute, there were a total of 1416 enterprises in China's bearing manufacturing industry in 2011, with an annual sales revenue of over 20 million yuan. The total industrial output value for the year was 193.211 billion yuan, a year-on-year increase of 27.59%; The sales revenue was 191.097 billion yuan, a year-on-year increase of 30.30%; The total profit was 12.523 billion yuan, an increase of 26.54% compared to the previous year.

In recent years, world-renowned enterprises have entered the Chinese bearing market and established production bases, such as SKF Group from Sweden, Schaeffler Group from Germany, Timken Company from the United States, NSK Company from Japan, NTN Company, etc. These companies not only operate globally but also manufacture globally. With their advantages in brand, equipment, technology, capital, and production scale, they have engaged in fierce competition with domestic-bearing enterprises. Currently, domestic enterprises mainly engage in the production of general bearings, while there are few specialized and high-end bearing production enterprises, and the technology is not yet mature. Therefore, for domestic enterprises to compete and even surpass advanced foreign-bearing brands, they still need to go through a long period of development path in terms of technology and other aspects.

During the 12th Five-Year Plan period, the effectiveness of national macroeconomic policies will continue to be evident, domestic economic growth will remain strong, international markets will also slowly recover, and the momentum of economic stabilization and recovery will gradually increase. The development of the national economy will drive investment in infrastructure, thereby promoting the development of industries such as metallurgy, electricity, construction machinery, building materials, and energy. At the same time, the country has issued ten major industrial revitalization plans to provide policy support for the development of industries such as automobiles, aerospace, machine tools, and wind power. The demand for bearings in these industries will gradually expand. In addition, the country's emphasis on the equipment manufacturing industry and the increasing trend of bearing localization will usher in a broader development space for China's bearing market. At the same time, with the development of China's bearing host industry, the product structure of shaft sleeves will change, and the proportion of high-end products in the products will increase. The sales unit price will also increase accordingly. It is expected that by 2015, China's bearing production is expected to exceed 28 billion sets, and its main business revenue is expected to reach 210 billion yuan, becoming the world's largest bearing production and sales base.

With the continuous intensification of competition in the bearing manufacturing industry, mergers and acquisitions and capital operations among large bearing manufacturing enterprises are becoming increasingly frequent. Excellent domestic-bearing manufacturing enterprises are paying more and more attention to the research of the industry market, especially in-depth research on the industrial development environment and product buyers. Because of this, a large number of domestic bearing manufacturing brands have rapidly risen and gradually become leaders in the bearing manufacturing industry!

English

English русский

русский Español

Español