-

Wheel Hub Bearings

Wheel Hub Bearings -

Wheel Hub Bearings

Wheel Hub BearingsDAC387436 DAC458045 Hub Deep Groove Ball Car Wheel Bearing

-

Spherical Bearings

Spherical BearingsFL204 FL205 FL206 Stainless Steel Pillow Block Bearing

-

Spherical Bearings

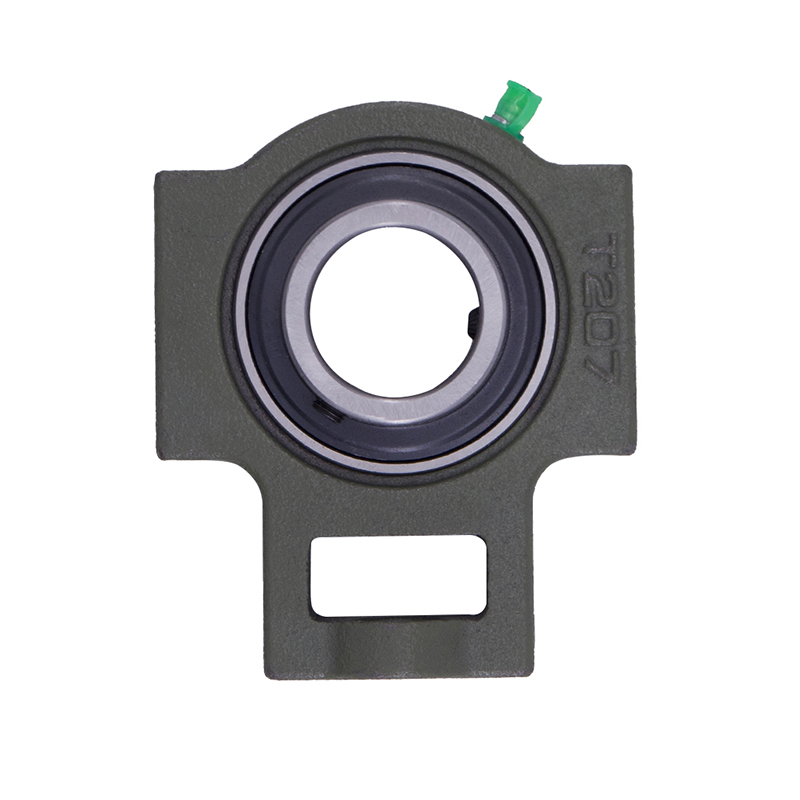

Spherical BearingsT204 T207 UC204 High Speed Insert Pillow Block Bearing

-

Spherical Bearings

Spherical BearingsFC204 F210 Auto Wheels Bike Pillow Block Bearing

-

Spherical Bearings

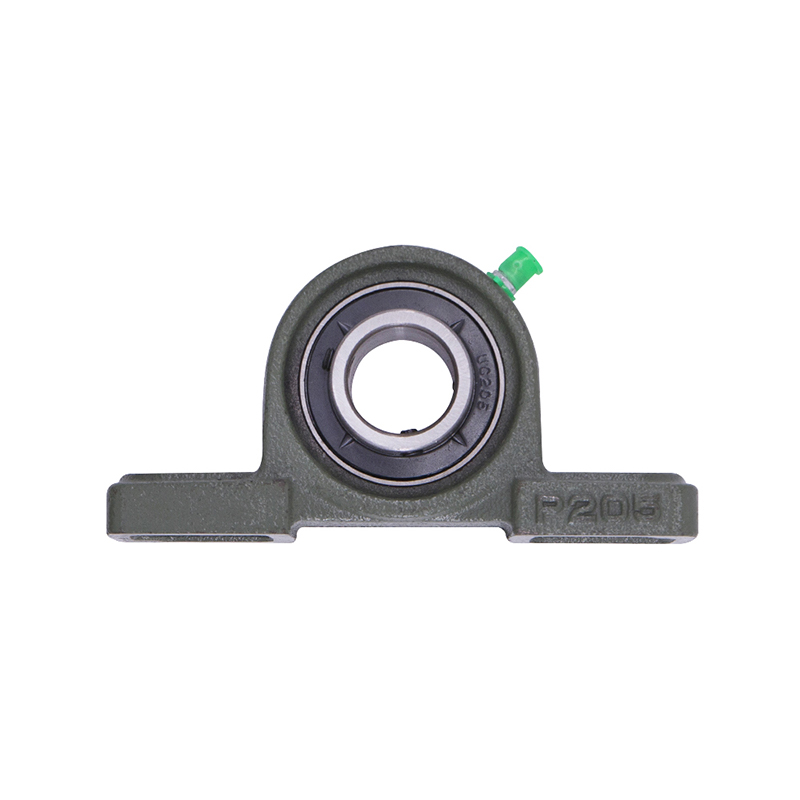

Spherical BearingsP207 206 205 203 High Precision Wheel Pillow Block Bearing

-

Thrust Roller Bearings

Thrust Roller BearingsS51100 S51107 S51109 Car Wheel Plain Thrust Ball Bearing

-

Thrust Roller Bearings

Thrust Roller Bearings51110 51107 51104 51206 High Speed Plain Thrust Ball Bearing

Application Requirements of Single Row Cylindrical Taper Roller Bearing

Industry news-Single Row Cylindrical Taper Roller Bearings are critical components in many industrial and mechanical applications. Their unique design allows them to handle both radial and axial loads, making them versatile and indispensable in various contexts.

Design and Structure

The Single Row Cylindrical Taper Roller Bearing features a unique geometry that combines the benefits of cylindrical and tapered designs. This bearing consists of:

Cylindrical Rollers: These provide the bearing with high radial load capacity, enabling it to support substantial weights perpendicular to the axis of rotation.

Tapered Inner and Outer Raceways: The tapered design allows the bearing to accommodate axial loads, or forces parallel to the axis of rotation, in one direction.

Single Row Configuration: This configuration offers a balance between load capacity and space efficiency, making the bearing suitable for applications where both factors are crucial.

Load Capabilities

One of the primary advantages of the Single Row Cylindrical Taper Roller Bearing is its ability to handle combined loads. This dual-load capability is essential for applications that experience both radial and axial forces. The bearing’s load capacities are influenced by several factors:

Radial Load: The cylindrical rollers provide significant support for radial loads, making the bearing ideal for heavy-duty applications such as machinery and automotive components.

Axial Load: The tapered raceways ensure that the bearing can also handle axial loads in one direction. This feature is particularly beneficial in applications where directional thrust is common, such as in gearboxes and differential systems.

Combined Load: The ability to support both radial and axial loads simultaneously makes the Single Row Cylindrical Taper Roller Bearing versatile and suitable for a wide range of applications.

Maintenance Requirements

Maintaining Single Row Cylindrical Taper Roller Bearings is crucial to ensure their longevity and performance. Regular maintenance practices include:

Lubrication: Proper lubrication reduces friction and wear, preventing premature failure. It is essential to use the correct type and amount of lubricant, following manufacturer recommendations.

Inspection: Regular inspections help identify signs of wear, such as pitting or spalling on the rollers and raceways. Early detection of issues can prevent more significant problems and extend the bearing’s lifespan.

Alignment: Ensuring that the bearing is correctly aligned during installation is critical. Misalignment can bring about uneven load distribution and accelerated wear.

Cleaning: Keeping the bearing and its surroundings clean prevents contaminants from entering and causing damage.

Specific Use Cases

Single Row Cylindrical Taper Roller Bearings are employed in various industries due to their robust performance characteristics. Some notable applications include:

Automotive Industry: These bearings are commonly used in automotive gearboxes and differential systems. Their ability to handle both radial and axial loads makes them ideal for supporting the shafts and gears within these systems.

Industrial Machinery: In heavy machinery, such as construction equipment and mining machines, Single Row Cylindrical Taper Roller Bearings provide reliable performance under heavy loads and harsh conditions.

Railway Systems: These bearings are essential in railway axle boxes, where they support both the weight of the rail vehicle and the dynamic forces encountered during travel.

Wind Turbines: The bearings are used in wind turbine gearboxes, where they handle the combined loads generated by wind forces and rotational motion.

Agricultural Equipment: In tractors and other agricultural machinery, Single Row Cylindrical Taper Roller Bearings contribute to the durability and efficiency of the equipment, ensuring reliable operation in demanding environments.

English

English русский

русский Español

Español