-

Wheel Hub Bearings

Wheel Hub Bearings -

Wheel Hub Bearings

Wheel Hub BearingsDAC387436 DAC458045 Hub Deep Groove Ball Car Wheel Bearing

-

Spherical Bearings

Spherical BearingsFL204 FL205 FL206 Stainless Steel Pillow Block Bearing

-

Spherical Bearings

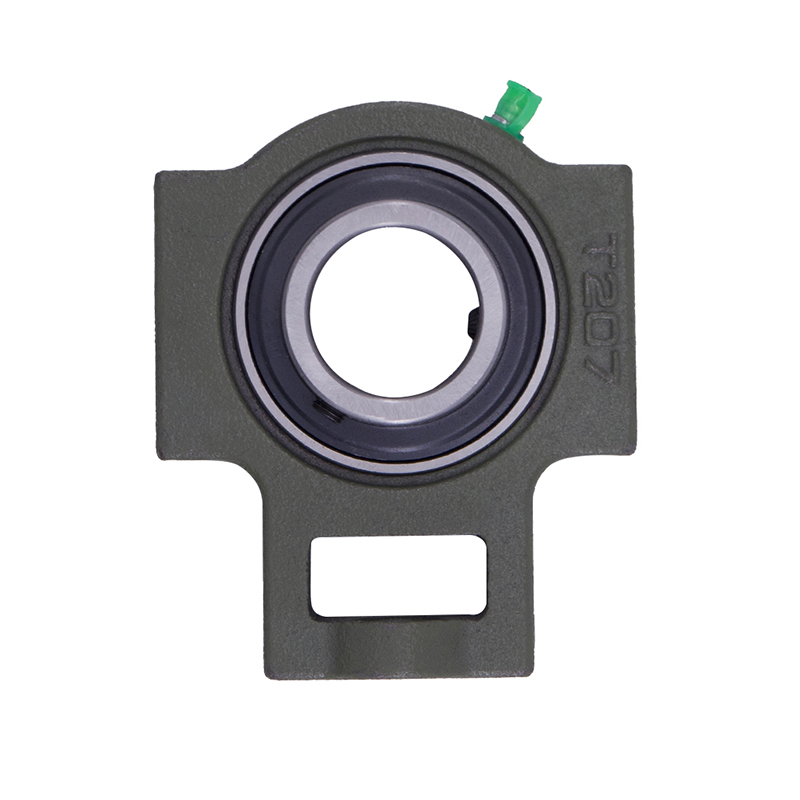

Spherical BearingsT204 T207 UC204 High Speed Insert Pillow Block Bearing

-

Spherical Bearings

Spherical BearingsFC204 F210 Auto Wheels Bike Pillow Block Bearing

-

Spherical Bearings

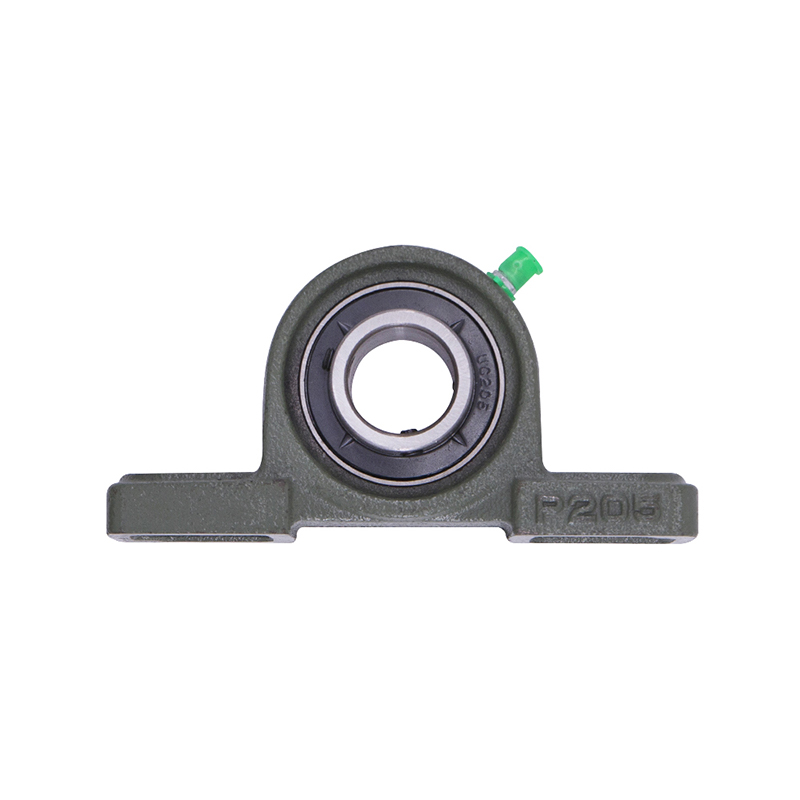

Spherical BearingsP207 206 205 203 High Precision Wheel Pillow Block Bearing

-

Thrust Roller Bearings

Thrust Roller BearingsS51100 S51107 S51109 Car Wheel Plain Thrust Ball Bearing

-

Thrust Roller Bearings

Thrust Roller Bearings51110 51107 51104 51206 High Speed Plain Thrust Ball Bearing

Exploring the Differences: Heavy Duty Bearings and Double Sealed Bearings 2 Inch

Industry news-Bearings play a critical role in machinery, facilitating smooth motion and reducing friction between moving parts. Among the many types of bearings available, heavy duty bearings and double sealed bearings 2 inch stand out for their specific applications and design features.

Heavy Duty Bearings: Strength and Durability

Heavy duty bearings are designed to withstand high loads, harsh environments, and demanding operating conditions. These bearings are used in applications where standard bearings would fail due to the intensity of the load or environmental factors.

Design and Construction

Heavy duty bearings typically feature robust construction materials such as high-carbon chromium steel or other alloy steels that offer exceptional strength and fatigue resistance. The bearing components, including the inner and outer rings, rolling elements, and cages, are engineered to handle heavy loads and provide long service life.

Load Capacity

One of the defining characteristics of heavy duty bearings is their high load capacity. These bearings are capable of supporting significant radial and axial loads, making them ideal for applications such as construction machinery, heavy-duty vehicles, industrial equipment, and mining machinery. The ability to handle heavy loads without excessive deformation or wear ensures the reliability and efficiency of the machinery.

Environmental Resistance

Heavy duty bearings are often used in environments where they are exposed to contaminants such as dust, dirt, water, and chemicals. To protect the bearings from these elements, they may be equipped with seals or shields. Additionally, the materials used in their construction are often treated or coated to enhance corrosion resistance.

Double Sealed Bearings 2 Inch: Protection and Efficiency

Double sealed bearings 2 inch are specifically designed to provide protection against contaminants while ensuring smooth and efficient operation. These bearings are used in applications where cleanliness and reduced maintenance are critical.

Design and Construction

Double sealed bearings feature seals on both sides of the bearing. These seals are typically made from rubber or other resilient materials that provide an effective barrier against contaminants. The bearing itself is made from high-quality steel, ensuring durability and precision.

Sealing Effectiveness

The primary advantage of double sealed bearings is their ability to keep out contaminants such as dust, dirt, and moisture. The seals prevent these particles from entering the bearing and interfering with the rolling elements. This protection is crucial in maintaining the bearing's performance and longevity, especially in environments where contamination is a concern.

Maintenance-Free Operation

Due to the effective sealing, double sealed bearings are often considered maintenance-free. The seals retain the lubrication within the bearing, reducing the need for regular re-lubrication. This feature is particularly beneficial in applications where access for maintenance is difficult or where reduce downtime is essential.

Load Capacity and Speed

Double sealed bearings are designed to handle moderate radial and axial loads. While they may not have the high load capacity of heavy duty bearings, they are suitable for many applications requiring reliable performance and protection against contaminants. Additionally, these bearings can operate at higher speeds due to their efficient design and lubrication retention.

Applications

Double sealed bearings 2 inch are used in a variety of applications across different industries. Common uses include:

Electric Motors: Bearings in electric motors require protection against dust and moisture to ensure smooth operation.

Conveyor Systems: Bearings in conveyor systems must handle continuous operation and exposure to contaminants.

Agricultural Machinery: Bearings in agricultural equipment are exposed to dirt and moisture, making effective sealing essential.

HVAC Systems: Bearings in HVAC units must operate efficiently and with minimal maintenance.

Household Appliances: Bearings in washing machines, dryers, and other appliances benefit from the maintenance-free design.

English

English русский

русский Español

Español