-

Wheel Hub Bearings

Wheel Hub Bearings -

Wheel Hub Bearings

Wheel Hub BearingsDAC387436 DAC458045 Hub Deep Groove Ball Car Wheel Bearing

-

Spherical Bearings

Spherical BearingsFL204 FL205 FL206 Stainless Steel Pillow Block Bearing

-

Spherical Bearings

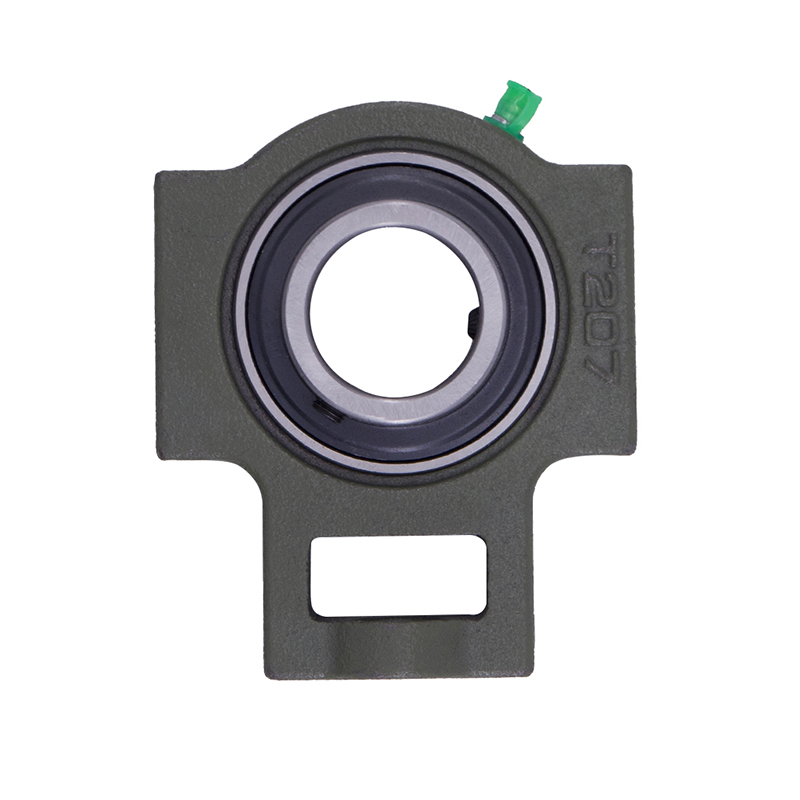

Spherical BearingsT204 T207 UC204 High Speed Insert Pillow Block Bearing

-

Spherical Bearings

Spherical BearingsFC204 F210 Auto Wheels Bike Pillow Block Bearing

-

Spherical Bearings

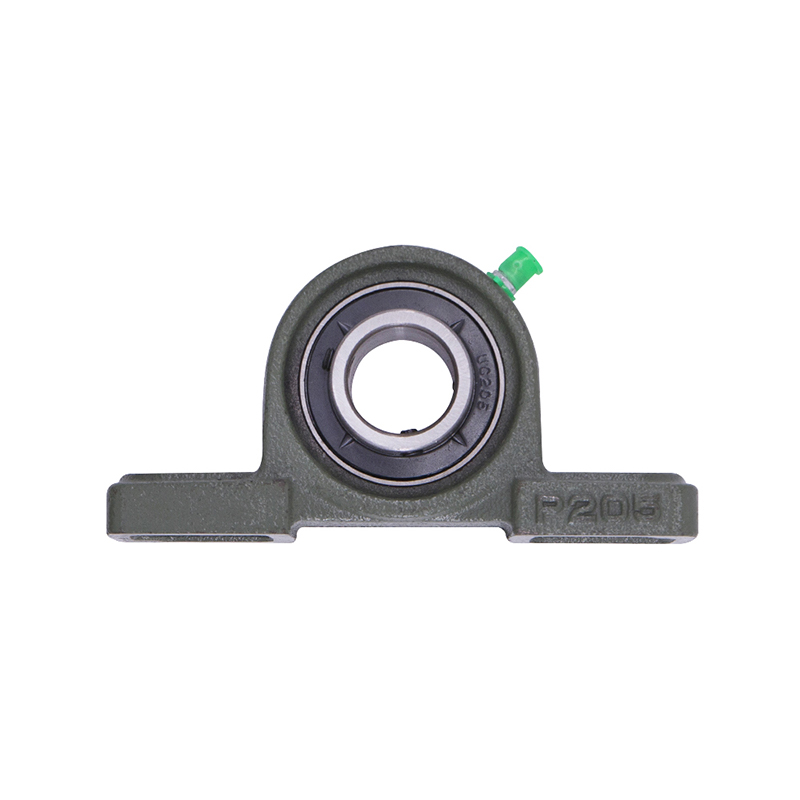

Spherical BearingsP207 206 205 203 High Precision Wheel Pillow Block Bearing

-

Thrust Roller Bearings

Thrust Roller BearingsS51100 S51107 S51109 Car Wheel Plain Thrust Ball Bearing

-

Thrust Roller Bearings

Thrust Roller Bearings51110 51107 51104 51206 High Speed Plain Thrust Ball Bearing

Performance analysis of boat wheel bearings

Industry news-Cheap price boat wheel bearings wholesaler

As the core component of the ship's transmission system, the performance of the boat wheel bearings directly affect the ship's operating efficiency, safety and economy. In the complex and changeable Marine environment, boat wheel bearings must have high bearing capacity, good sealing, corrosion resistance and the ability to adapt to various working conditions. This paper will deeply discuss the performance analysis of boat wheel bearings, including key performance indicators, influencing factors and evaluation methods.

Key performance indicator

Bearing capacity: boat wheel bearings need to withstand radial and axial loads from ship movement, and their bearing capacity is the basis for measuring bearing performance. The high bearing capacity ensures the stability and reliability of bearings under heavy load conditions.

Friction coefficient: The friction coefficient directly affects the efficiency and life of the bearing. The low friction coefficient helps to reduce energy loss and improve the propulsion efficiency of the ship.

Corrosion resistance: salt water and moisture in the Marine environment have a corrosive effect on bearing materials, and corrosion resistance is the key to ensure long-term stable operation of bearings.

Sealing: Good sealing can prevent sea water and dirt from entering the bearing inside, while keeping the lubricant from being lost, which is essential for extending the bearing life.

Aligning performance: The ship will encounter the influence of waves and wind during navigation, and the aligning performance enables the bearing to adapt to small shifts in the shaft, reducing vibration and noise.

Influencing factor

Material selection: The hardness, strength and corrosion resistance of boat wheel bearings materials directly affect its performance. For example, stainless steel and special alloy materials are widely used for their great corrosion resistance and mechanical properties.

Lubrication method: Proper lubrication can significantly reduce the coefficient of friction and improve the bearing capacity and life. Oil lubrication and grease lubrication have their own advantages and disadvantages. Choosing the right lubrication method is very important to the performance of boat wheel bearings.

Working environment: temperature, humidity, salinity and other environmental factors have a significant impact on the performance of boat wheel bearings. High temperature will accelerate lubricant aging, while high salinity will increase corrosion.

Maintenance: Regular inspection, cleaning and lubrication are the key to maintaining boat wheel bearings performance. Neglect of maintenance can cause premature bearing failure.

Evaluation method

Theoretical calculation: Through mechanical analysis and fluid dynamics model, the performance parameters of bearings under different working conditions are predicted, such as bearing capacity, friction coefficient and temperature distribution.

Experimental test: Simulate the actual working conditions under laboratory conditions, and verify the theoretical calculation results by testing the bearing bearing capacity, friction coefficient and corrosion resistance.

On-site monitoring: Sensors are installed on the ship to monitor bearing vibration, temperature and lubrication status in real time, collecting data for performance evaluation and fault warning.

User feedback: Collect the experience of crew and maintenance personnel, understand the performance of bearings in actual operation, and provide a basis for performance improvement.

conclusion

The performance analysis of boat wheel bearings is a comprehensive process, involving material science, fluid mechanics, mechanical design and other fields. By means of theoretical calculation, experimental testing, field monitoring and user feedback, the bearing performance can be comprehensively evaluated, providing a scientific basis for ship design, maintenance and optimization. With the continuous progress of material technology, lubrication technology and monitoring technology, the performance of boat wheel bearings will be further improved, and new vitality will be injected into the development of the Marine industry.

English

English русский

русский Español

Español