-

Wheel Hub Bearings

Wheel Hub Bearings -

Wheel Hub Bearings

Wheel Hub BearingsDAC387436 DAC458045 Hub Deep Groove Ball Car Wheel Bearing

-

Spherical Bearings

Spherical BearingsFL204 FL205 FL206 Stainless Steel Pillow Block Bearing

-

Spherical Bearings

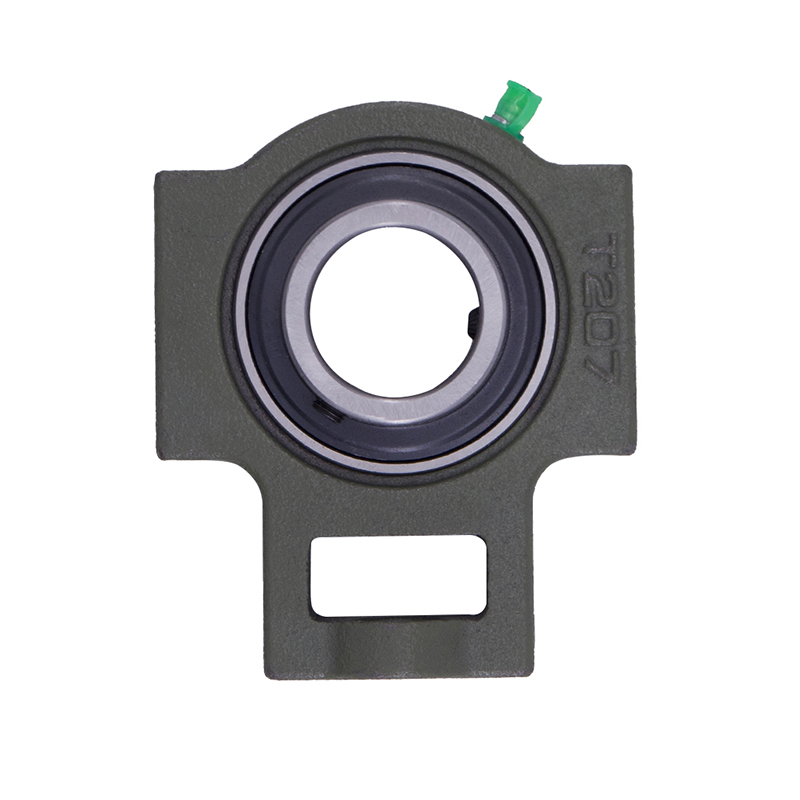

Spherical BearingsT204 T207 UC204 High Speed Insert Pillow Block Bearing

-

Spherical Bearings

Spherical BearingsFC204 F210 Auto Wheels Bike Pillow Block Bearing

-

Spherical Bearings

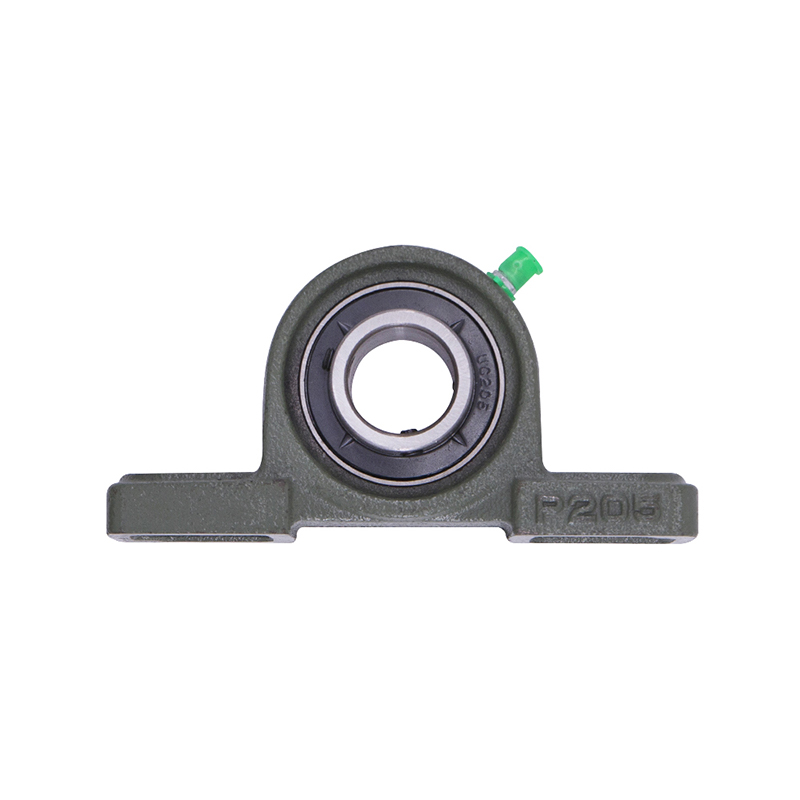

Spherical BearingsP207 206 205 203 High Precision Wheel Pillow Block Bearing

-

Thrust Roller Bearings

Thrust Roller BearingsS51100 S51107 S51109 Car Wheel Plain Thrust Ball Bearing

-

Thrust Roller Bearings

Thrust Roller Bearings51110 51107 51104 51206 High Speed Plain Thrust Ball Bearing

Performance characteristics of ball bearing block

Industry news-Cheap price ball bearing block wholesaler

As an important part of the mechanical transmission system, the performance index of the ball bearing block plays a crucial role in the operating efficiency, accuracy and reliability of the entire equipment. Bearing capacity, precision, friction coefficient and sealing performance are the key indicators to measure the performance of the ball bearing block.

Bearing capacity is a core performance index of ball bearing block. It determines the load that the bearing seat can bear in the work. Different types and specifications of ball bearing blocks have different bearing capacities. In general, its carrying capacity is affected by many factors such as material strength, structural design, and manufacturing process. For example, ball bearing blocks made of high-strength alloy steel are able to withstand greater radial and axial loads. In some heavy machinery, such as large cranes, mining equipment, etc., it is necessary to choose a ball bearing block with high carrying capacity to ensure the stable operation of the equipment under harsh conditions.

Accuracy is another important performance indicator of ball bearing block. The high-precision ball bearing block can effectively reduce the runout and swing of the rotating shaft, thereby improving the processing accuracy and operating stability of the equipment. For CNC machine tools, precision instruments and other equipment with high precision requirements, the accuracy of the ball bearing block directly affects the quality and performance of the product. High-precision ball bearing blocks usually adopt precision machining processes and strictly control dimensional tolerances and shape and position tolerances to ensure that they can meet the high-precision requirements of the equipment.

The friction coefficient is also one of the key factors to measure the performance of the ball bearing block. The lower friction coefficient means that less friction is generated during rotation, which can reduce energy loss, improve the operating efficiency of the equipment, reduce the operating temperature, and extend the service life. In order to reduce the coefficient of friction, the ball bearing block is usually made of high-quality lubrication materials and reasonable lubrication methods. At the same time, optimizing the internal structural design of the bearing seat, such as reducing the contact area and improving the roughness of the contact surface, can also effectively reduce the friction coefficient.

Sealing performance is also crucial for the proper operation of the ball bearing block. A good seal can prevent dust, impurities, moisture, etc. from entering the bearing interior, avoid the leakage of lubricating grease, so as to protect the ball and raceway from wear and corrosion, and extend the service life of the bearing. Different working environments have different requirements for sealing performance. In harsh environments, such as dusty, wet or corrosive media, it is necessary to use a ball bearing block with higher sealing performance, such as the use of multiple sealing structures or the use of special sealing materials.

For example, in the wheel hub bearing housing of a car, the bearing capacity and sealing performance are key. In the process of driving, the wheel hub must bear the weight of the vehicle and the impact and vibration from the road surface, so the bearing seat with a high bearing capacity is required. At the same time, in order to prevent water, dust, etc. from entering the bearing interior, affecting its service life and performance, the hub bearing seat must have good sealing performance.

In short, bearing capacity, accuracy, friction coefficient and sealing performance are important performance indicators of ball bearing block. In practical applications, the ball bearing block with appropriate performance indicators should be selected according to the specific working conditions and requirements to ensure the normal operation and efficient work of the equipment. With the continuous progress of science and technology and the continuous improvement of manufacturing process, the performance of the ball bearing block is also constantly optimized and improved, providing more powerful support for the development of various types of mechanical equipment.

English

English русский

русский Español

Español