-

Wheel Hub Bearings

Wheel Hub Bearings -

Wheel Hub Bearings

Wheel Hub BearingsDAC387436 DAC458045 Hub Deep Groove Ball Car Wheel Bearing

-

Spherical Bearings

Spherical BearingsFL204 FL205 FL206 Stainless Steel Pillow Block Bearing

-

Spherical Bearings

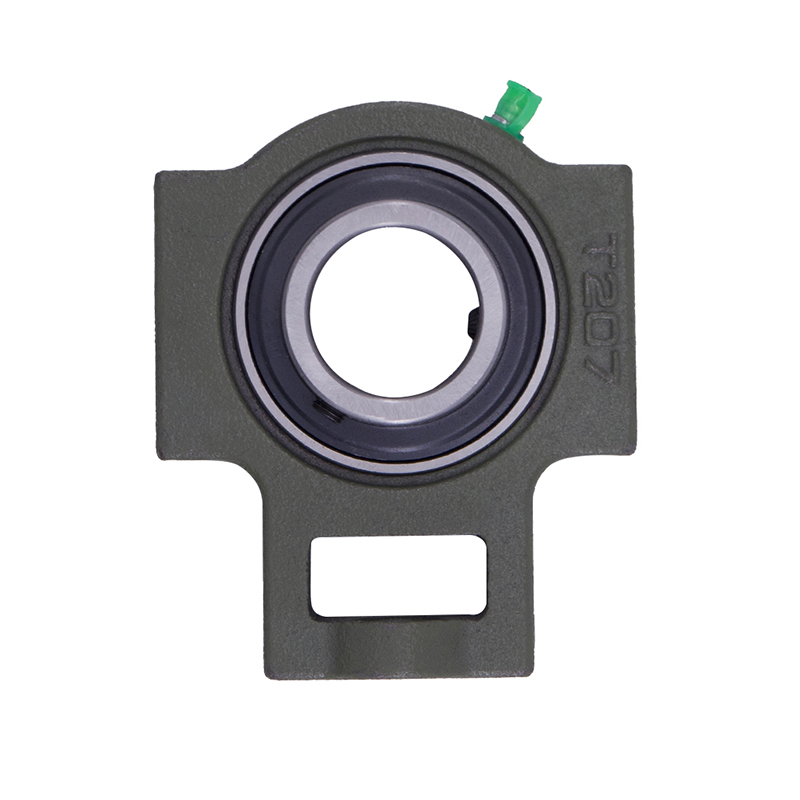

Spherical BearingsT204 T207 UC204 High Speed Insert Pillow Block Bearing

-

Spherical Bearings

Spherical BearingsFC204 F210 Auto Wheels Bike Pillow Block Bearing

-

Spherical Bearings

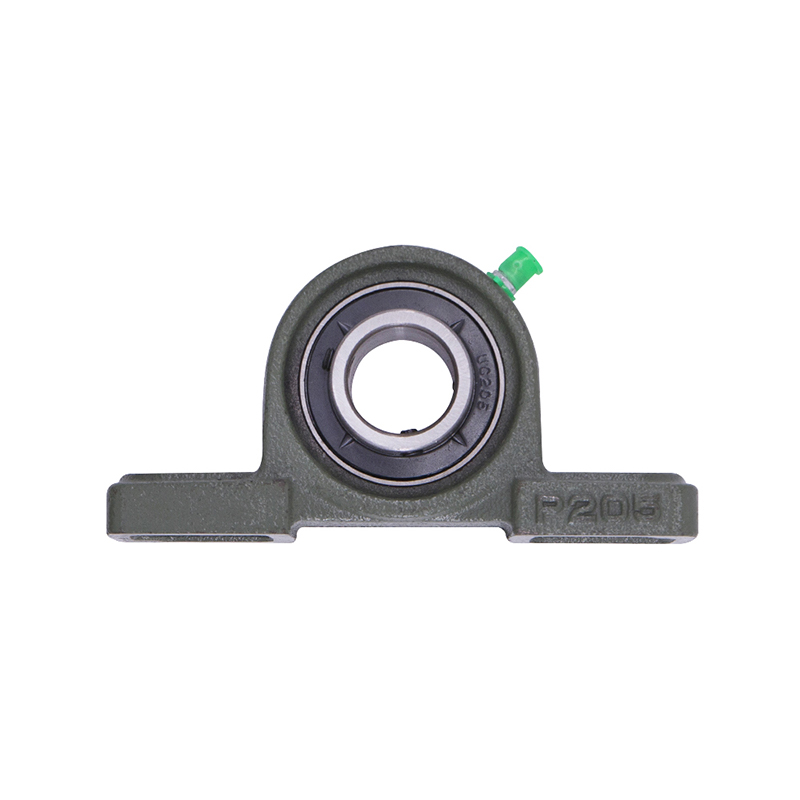

Spherical BearingsP207 206 205 203 High Precision Wheel Pillow Block Bearing

-

Thrust Roller Bearings

Thrust Roller BearingsS51100 S51107 S51109 Car Wheel Plain Thrust Ball Bearing

-

Thrust Roller Bearings

Thrust Roller Bearings51110 51107 51104 51206 High Speed Plain Thrust Ball Bearing

Standards for High Precision Flanged Linear Ball Bearings

Industry news-High precision flanged linear ball bearings are critical components in various industrial applications, ensuring smooth and accurate linear motion. To guarantee their performance and reliability, these bearings must adhere to several key standards and specifications.

Dimensional Accuracy

One of the primary standards high precision flanged linear ball bearings must meet is dimensional accuracy. The bearings should conform to precise dimensions and tolerances to ensure a proper fit within the housing and compatibility with the shaft. Standards such as ISO 10285 and ISO 12090-1 provide guidelines for the dimensions and tolerances of linear motion rolling bearings, ensuring consistent and reliable performance across different manufacturers and applications.

Material Quality

The materials used in manufacturing high precision flanged linear ball bearings must meet stringent quality standards to ensure durability and resistance to wear and corrosion. Commonly, these bearings are made from high-grade stainless steel or chrome steel, offering good hardness and longevity. Standards like ISO 683-17 and ISO 683-18 specify the requirements for the material properties of bearing steels, ensuring they can withstand demanding operational conditions.

Load Capacity and Durability

High precision flanged linear ball bearings should be capable of handling the specified loads and maintaining performance over extended periods. ISO 281 provides guidelines for calculating the dynamic and static load ratings of bearings, ensuring they can support the required loads without deformation or failure. Additionally, ISO 76 specifies the methods for determining the static load rating, which is crucial for applications involving heavy loads or impacts.

Noise and Vibration

High precision flanged linear ball bearings must operate quietly and with minimal vibration to ensure smooth and accurate motion. Standards such as ISO 15242-1 and ISO 15242-2 provide guidelines for measuring and controlling noise and vibration levels in rolling bearings, ensuring they meet the required performance criteria for high-precision applications.

Industry Uses of Self-Aligning Linear Bearings

Self-aligning linear bearings are vital components in many industrial applications, offering the unique ability to accommodate misalignments and ensure smooth linear motion. Their versatility and adaptability make them suitable for a wide range of uses across different industries.

Manufacturing and Automation

In the manufacturing and automation sectors, self-aligning linear bearings are commonly used in automated assembly lines, CNC machines, and robotic systems. These bearings help maintain precise linear motion even when there are slight misalignments between the components, reducing wear and tear and ensuring consistent performance. For instance, in CNC machines, self-aligning linear bearings enable accurate and smooth movement of the cutting tools, enhancing the precision and quality of the machined parts.

Printing and Packaging

The printing and packaging industries also benefit from the use of self-aligning linear bearings. In printing presses and packaging machines, these bearings facilitate the smooth and accurate movement of print heads and packaging materials. The self-aligning feature helps compensate for any misalignments in the machine components, reducing downtime and maintenance costs while improving productivity and efficiency.

Medical Equipment

Self-aligning linear bearings are crucial in the medical field, particularly in diagnostic and treatment equipment such as MRI machines, CT scanners, and patient positioning systems. These bearings ensure the precise and smooth movement of components, contributing to the accuracy and reliability of the equipment. The self-aligning capability helps maintain performance even in the presence of minor misalignments, enhancing the overall functionality and longevity of the medical devices.

Aerospace and Defense

In the aerospace and defense industries, self-aligning linear bearings are used in various applications, including aircraft control systems, missile guidance systems, and satellite positioning mechanisms. These bearings provide the necessary precision and reliability required for critical operations, accommodating any misalignments and ensuring smooth and accurate motion. Their robust design and ability to handle challenging conditions make them ideal for use in aerospace and defense applications.

English

English русский

русский Español

Español