-

Wheel Hub Bearings

Wheel Hub Bearings -

Wheel Hub Bearings

Wheel Hub BearingsDAC387436 DAC458045 Hub Deep Groove Ball Car Wheel Bearing

-

Spherical Bearings

Spherical BearingsFL204 FL205 FL206 Stainless Steel Pillow Block Bearing

-

Spherical Bearings

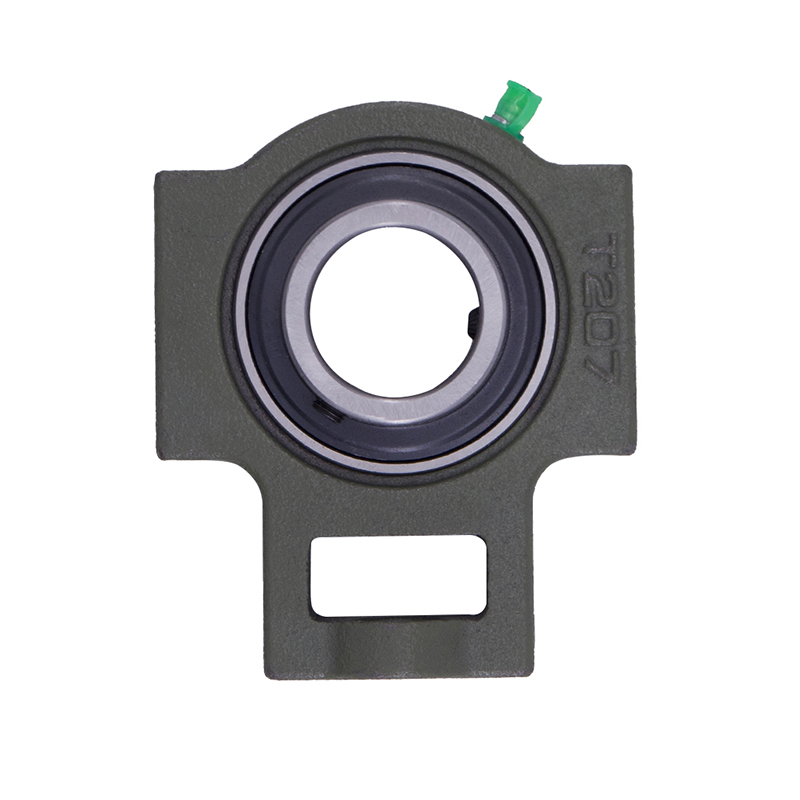

Spherical BearingsT204 T207 UC204 High Speed Insert Pillow Block Bearing

-

Spherical Bearings

Spherical BearingsFC204 F210 Auto Wheels Bike Pillow Block Bearing

-

Spherical Bearings

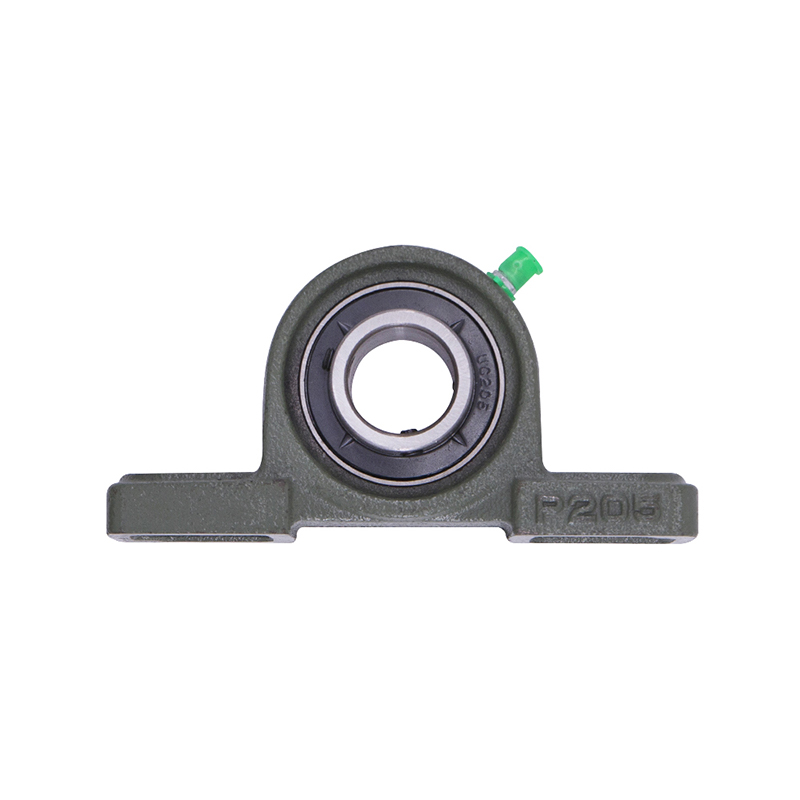

Spherical BearingsP207 206 205 203 High Precision Wheel Pillow Block Bearing

-

Thrust Roller Bearings

Thrust Roller BearingsS51100 S51107 S51109 Car Wheel Plain Thrust Ball Bearing

-

Thrust Roller Bearings

Thrust Roller Bearings51110 51107 51104 51206 High Speed Plain Thrust Ball Bearing

The Versatility of Tapered Bearings: Exploring Taper Roller Ball Bearings

Industry news-Taper Roller Ball Bearings are integral components in various mechanical systems, known for their ability to handle combined radial and axial loads. These bearings are designed with tapered inner and outer ring raceways and tapered rollers, which align with the bearing axis. This unique design allows Taper Roller Ball Bearings to manage significant loads and operate efficiently under high-stress conditions.

The tapered design of these bearings ensures that the load is evenly distributed along the roller's length, reducing stress concentration and enhancing durability. This feature makes them ideal for applications such as automotive wheel hubs, where they must endure both the vehicle's weight and lateral forces during turning. Additionally, Taper Roller Ball Bearings are widely used in industrial gearboxes, agricultural machinery, and construction equipment, where robust performance and reliability are critical.

Another advantage of Taper Roller Ball Bearings is their ability to accommodate misalignment between the shaft and housing. This flexibility reduces the risk of premature bearing failure and extends the service life of the machinery. Furthermore, these bearings can be customized with various materials, seals, and lubricants to suit specific operating conditions, making them versatile and adaptable to a wide range of applications.

Tapered Cone Bearings are a specific type of tapered roller bearing, featuring a conical shape that helps manage complex loading conditions. These bearings consist of an inner ring, outer ring, and tapered rollers that fit within the conical shape of the rings. The tapered rollers are positioned between the inner and outer raceways, allowing them to support both radial and axial loads efficiently.

The primary advantage of Tapered Cone Bearings is their high load-carrying capacity. The conical design ensures that the load is spread evenly across the rollers, reducing wear and extending the bearing's lifespan. This feature makes Tapered Cone Bearings particularly suitable for heavy-duty applications such as mining equipment, heavy machinery, and railway axle boxes, where they must withstand substantial loads and harsh operating conditions.

Another key benefit of Tapered Cone Bearings is their ability to handle misalignment. The tapered shape allows for slight angular adjustments, accommodating misalignment between the shaft and housing without compromising performance. This capability is essential in applications where precise alignment is challenging to maintain, such as in off-road vehicles and construction equipment.

Tapered Cone Bearings also offer ease of maintenance and replacement. Their design allows for the rollers and raceways to be easily inspected and replaced when necessary, reducing downtime and ensuring continuous operation. This ease of maintenance makes them a cost-effective choice for many industrial applications.

Tapered Needle Bearings are another type of tapered bearing that combines the benefits of needle roller bearings and tapered roller bearings. These bearings feature long, thin rollers that are tapered along their length, allowing them to handle high radial loads and moderate axial loads. The tapered design ensures that the load is distributed evenly across the rollers, reducing wear and extending the bearing's service life.

One of the primary advantages of Tapered Needle Bearings is their compact design. The thin, tapered rollers allow these bearings to fit into smaller spaces while still providing high load-carrying capacity. This makes them ideal for applications with limited space, such as in automotive transmissions, where they can efficiently handle the combined loads without occupying much room.

Another significant benefit of Tapered Needle Bearings is their ability to handle high-speed operations. The thin rollers reduce friction and heat generation, allowing these bearings to operate smoothly at high speeds. This feature is particularly valuable in applications such as electric motors and power tools, where efficient performance at high speeds is essential.

Tapered Needle Bearings are also known for their durability and reliability. The even load distribution and robust construction ensure that these bearings can withstand heavy loads and harsh operating conditions without experiencing premature failure. This reliability makes them suitable for demanding applications such as agricultural machinery, construction equipment, and industrial gearboxes.

English

English русский

русский Español

Español