-

Wheel Hub Bearings

Wheel Hub Bearings -

Wheel Hub Bearings

Wheel Hub BearingsDAC387436 DAC458045 Hub Deep Groove Ball Car Wheel Bearing

-

Spherical Bearings

Spherical BearingsFL204 FL205 FL206 Stainless Steel Pillow Block Bearing

-

Spherical Bearings

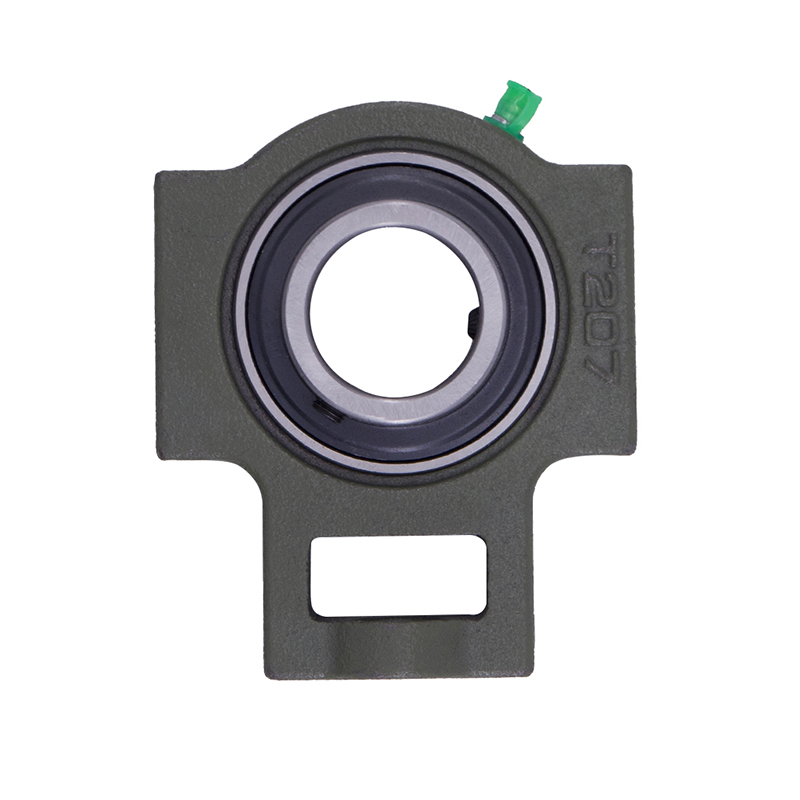

Spherical BearingsT204 T207 UC204 High Speed Insert Pillow Block Bearing

-

Spherical Bearings

Spherical BearingsFC204 F210 Auto Wheels Bike Pillow Block Bearing

-

Spherical Bearings

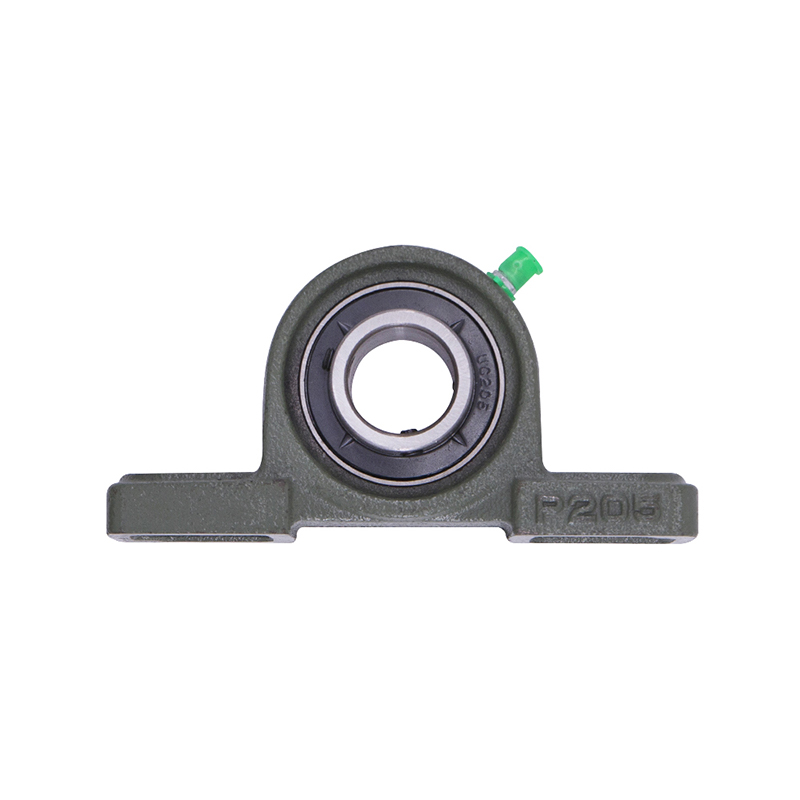

Spherical BearingsP207 206 205 203 High Precision Wheel Pillow Block Bearing

-

Thrust Roller Bearings

Thrust Roller BearingsS51100 S51107 S51109 Car Wheel Plain Thrust Ball Bearing

-

Thrust Roller Bearings

Thrust Roller Bearings51110 51107 51104 51206 High Speed Plain Thrust Ball Bearing

Working Principle of the 6208 Bearing

Industry news-Wholesale 6208 bearing factory in China

The 6208 bearing is a commonly used deep groove ball bearing, widely applied in various machinery due to its simple structure and reliable performance. This article will delve into the internal structure, operational mechanism, rotation principle, load distribution, and friction reduction of the 6208 bearing, providing a comprehensive understanding of its working principles.

1. Basic Definition of the 6208 Bearing

The 6208 bearing belongs to the deep groove ball bearing series and is primarily composed of an inner ring, outer ring, rolling elements (steel balls), and a cage. This type of bearing is designed to handle radial loads and moderate axial loads, making it suitable for high-speed applications and medium loads.

2. Internal Structure

The internal structure of the 6208 bearing includes the following components:

Inner Ring (Inner Race): This component fits onto the shaft and rotates with it.

Outer Ring (Outer Race): This component fits into the bearing housing or machine frame and remains stationary.

Rolling Elements (Steel Balls): These are the balls that support the load and reduce friction.

Cage: This separates and guides the rolling elements, ensuring they are evenly distributed and do not come into contact with each other.

3. Operational Mechanism

The operational mechanism of the 6208 bearing is based on the principle of rolling friction, which involves the rolling elements moving between the inner and outer rings to transmit loads, thereby reducing sliding friction and improving efficiency and longevity.

Movement of Rolling Elements: When the shaft rotates, the inner ring rotates with it, while the outer ring remains stationary. The rolling elements roll between the raceways of the inner and outer rings, transmitting the load through their rolling motion.

Role of the Cage: The cage keeps the rolling elements evenly spaced and prevents them from touching each other, reducing friction and wear, and ensuring smooth operation.

4. Rotation Principle

The rotation principle of the 6208 bearing is based on its deep groove design, which allows the inner and outer rings to accommodate more rolling elements, thus enhancing load capacity and stability.

Deep Groove Design: The raceways of the inner and outer rings are designed with deep grooves, allowing more rolling elements to be accommodated, increasing the contact area and load capacity.

Rolling Motion: The rolling elements roll within the raceways, transmitting the load through their rolling motion, which reduces sliding friction and improves efficiency.

Lubrication: Proper lubrication further reduces the friction between the rolling elements and the raceways, lowering temperatures and extending the bearing's lifespan.

5. Load Distribution

The 6208 bearing is designed to effectively distribute and bear radial loads and certain axial loads. Its load distribution mechanism works as follows:

Radial Loads: When the bearing is subjected to radial loads, the rolling elements roll between the raceways of the inner and outer rings, distributing the load evenly across the entire raceway, reducing localized stress concentrations.

Axial Loads: Although the 6208 bearing is primarily designed for radial loads, it can also handle certain axial loads. Axial loads are transmitted through the rolling elements to the inner and outer rings, but due to the deep groove design, the axial load capacity is relatively limited.

6. Friction Reduction

The 6208 bearing employs several methods to reduce friction, enhancing operational efficiency and lifespan:

Rolling Friction: Compared to sliding friction, rolling friction has a lower coefficient, significantly reducing energy loss and wear.

Lubricants: Proper lubricants further reduce the friction between the rolling elements and the raceways, lowering temperatures and extending the bearing's lifespan.

Cage Design: The cage design ensures that the rolling elements are evenly distributed, reducing contact between them and further reducing friction.

7. Application Examples

The 6208 bearing is widely used in many types of machinery, such as:

Electric Motors: The 6208 bearing is commonly used to support the rotor in electric motors, ensuring smooth operation and reducing vibration and noise.

Pumps and Fans: The 6208 bearing supports the shafts in pumps and fans, handling radial and axial loads to ensure efficient operation.

Agricultural Machinery: The 6208 bearing is used in agricultural machinery to support drive shafts, handling complex load conditions and ensuring reliability and durability.

Summary

The 6208 bearing, as a deep groove ball bearing, is a critical component in many machines due to its simple structure, reliable performance, and wide range of applications. Understanding its internal structure, operational mechanism, rotation principle, load distribution, and friction reduction can help in selecting and using this bearing effectively, ensuring the efficient and stable operation of machinery. We hope this article provides valuable insights into the working principles of the 6208 bearing.

English

English русский

русский Español

Español