-

Wheel Hub Bearings

Wheel Hub BearingsDAC387436 DAC458045 Hub Deep Groove Ball Car Wheel Bearing

-

Spherical Bearings

Spherical BearingsFL204 FL205 FL206 Stainless Steel Pillow Block Bearing

-

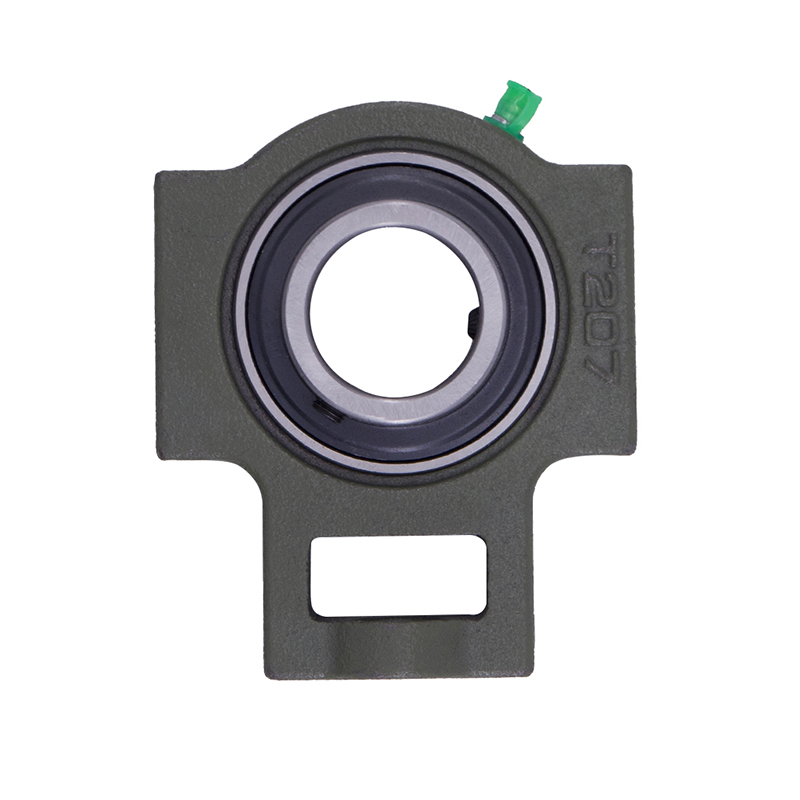

Spherical Bearings

Spherical BearingsT204 T207 UC204 High Speed Insert Pillow Block Bearing

-

Spherical Bearings

Spherical BearingsFC204 F210 Auto Wheels Bike Pillow Block Bearing

-

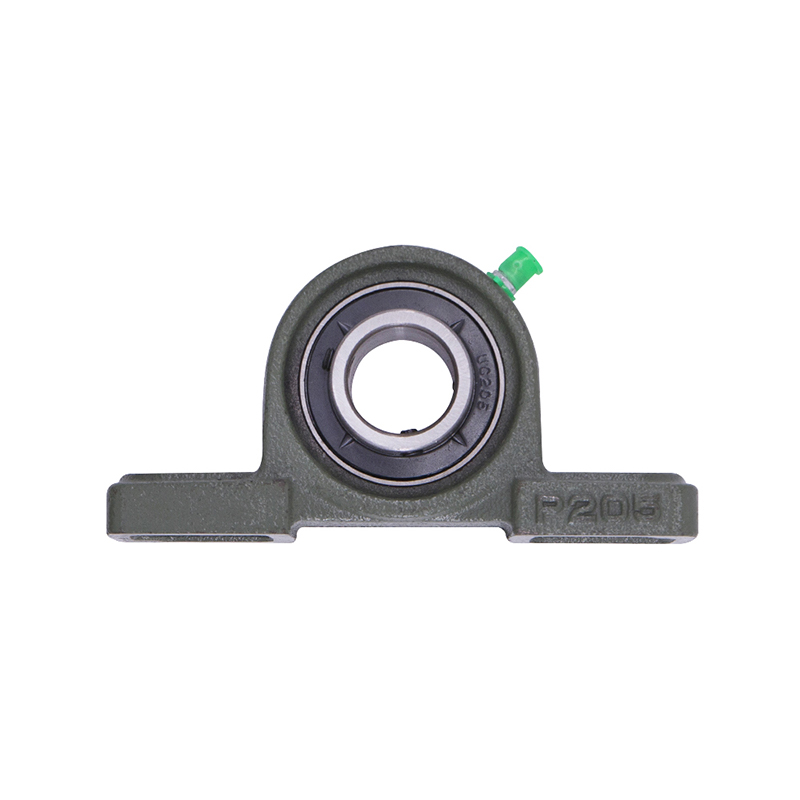

Spherical Bearings

Spherical BearingsP207 206 205 203 High Precision Wheel Pillow Block Bearing

-

Thrust Roller Bearings

Thrust Roller BearingsS51100 S51107 S51109 Car Wheel Plain Thrust Ball Bearing

-

Thrust Roller Bearings

Thrust Roller Bearings51110 51107 51104 51206 High Speed Plain Thrust Ball Bearing

Applications of 3/4 Inch Pillow Block Bearings

Pillow block bearings are essential components in many mechanical systems. The 3/4 inch pillow block bearings, with their specific dimensions and characteristics, are particularly versatile and suitable for a wide range of applications.

Agricultural Machinery

In the agricultural sector, reliability and durability are crucial. 3/4 inch pillow block bearings are commonly used in farm equipment such as tillers, mowers, and harvesters. These bearings are capable of handling moderate loads and can withstand the dusty and often harsh conditions of agricultural environments. Their ease of maintenance and replacement also makes them ideal for equipment that must remain operational during critical planting and harvesting periods.

Conveyor Systems

Conveyor systems are ubiquitous in manufacturing, packaging, and distribution facilities. The 3/4 inch pillow block bearings are good for supporting the shafts of conveyor belts, providing smooth and efficient movement of goods. Their robust design ensures they can handle continuous operation and varying loads, making them integral to maintaining the efficiency and reliability of conveyor systems.

HVAC Systems

Heating, ventilation, and air conditioning (HVAC) systems rely heavily on rotating parts to circulate air and regulate temperature. 3/4 inch pillow block bearings are used in fans, blowers, and other rotating components within these systems. Their ability to operate quietly and efficiently ensures that HVAC systems can maintain comfortable indoor environments without excessive noise or vibration.

Industrial Machinery

In various industrial applications, 3/4 inch pillow block bearings are used in machinery that requires reliable rotation and support for shafts. This includes equipment like pumps, mixers, and small-scale production machines. The bearings' capacity to handle both radial and axial loads makes them suitable for diverse industrial processes, enhancing the machinery's operational stability and longevity.

Installation of 2 Inch High Temp Pillow Block Bearings

High temperature pillow block bearings are designed to perform under heat conditions, making them ideal for applications where standard bearings would fail. Installing 2 inch high temp pillow block bearings requires careful attention to ensure performance and longevity. Here’s a step-by-step guide to the installation process.

Preparation

Before starting the installation, gather all necessary tools and materials, including the high temp pillow block bearings, mounting bolts, a torque wrench, and lubrication appropriate for high-temperature conditions. Ensure the mounting surface is clean and free of debris to provide a stable and secure base for the bearing.

Align the Bearing

Position the bearing on the mounting surface, aligning the holes of the bearing housing with the pre-drilled holes on the mounting base. Proper alignment is crucial to avoid misalignment issues that can bring about premature wear or failure. Use alignment tools if necessary to ensure the bearing is positioned.

Secure the Bearing

Insert the mounting bolts through the housing holes and into the mounting surface. Using a torque wrench, tighten the bolts to the manufacturer’s specified torque settings. It’s important to follow the torque specifications to prevent overtightening, which can damage the bearing or mounting surface, and undertightening, which can bring about instability and vibration.

Lubrication

Proper lubrication is essential for the smooth operation and longevity of high temp pillow block bearings. Apply the appropriate high-temperature grease or oil to the bearing according to the manufacturer’s recommendations. Over-lubrication or under-lubrication can both bring about operational issues, so it’s important to apply the correct amount.

Final Checks

After installation, rotate the bearing manually to ensure it moves smoothly without any resistance or unusual noises. Check for proper alignment and secure attachment to the mounting surface. Monitor the bearing during the initial operation to ensure it is functioning correctly under the actual working conditions.

Maintenance

Regular maintenance is key to extending the lifespan of high temp pillow block bearings. Periodically check the bearing for signs of wear, ensure it remains properly lubricated, and tighten the mounting bolts if necessary. Operating in high-temperature environments can accelerate wear, so more frequent inspections may be required compared to standard bearings.

English

English русский

русский Español

Español