-

Wheel Hub Bearings

Wheel Hub Bearings -

Wheel Hub Bearings

Wheel Hub BearingsDAC387436 DAC458045 Hub Deep Groove Ball Car Wheel Bearing

-

Spherical Bearings

Spherical BearingsFL204 FL205 FL206 Stainless Steel Pillow Block Bearing

-

Spherical Bearings

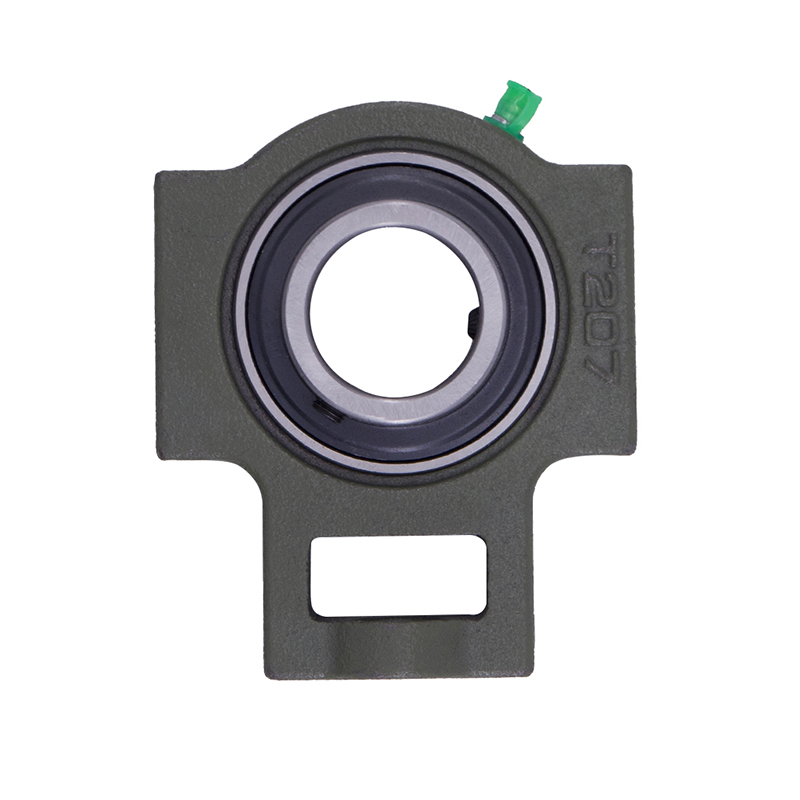

Spherical BearingsT204 T207 UC204 High Speed Insert Pillow Block Bearing

-

Spherical Bearings

Spherical BearingsFC204 F210 Auto Wheels Bike Pillow Block Bearing

-

Spherical Bearings

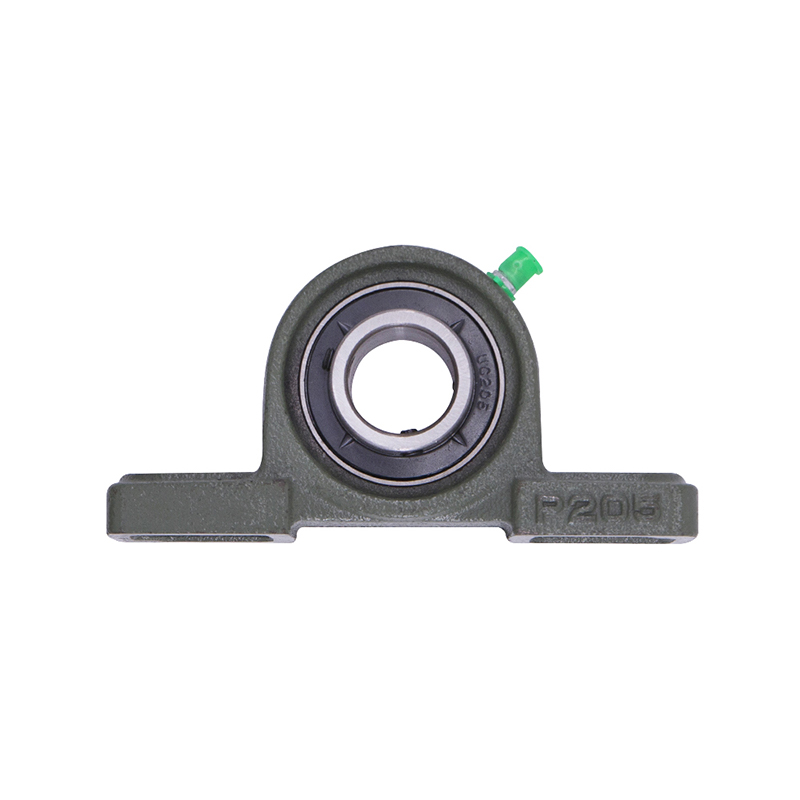

Spherical BearingsP207 206 205 203 High Precision Wheel Pillow Block Bearing

-

Thrust Roller Bearings

Thrust Roller BearingsS51100 S51107 S51109 Car Wheel Plain Thrust Ball Bearing

-

Thrust Roller Bearings

Thrust Roller Bearings51110 51107 51104 51206 High Speed Plain Thrust Ball Bearing

Introduction to Imperial Single Deep Groove Ball Bearings

Industry news-Imperial single deep groove ball bearings are essential components in many mechanical systems, designed to provide smooth and efficient operation. These bearings, known for their versatility and durability, come in various sizes and configurations to fit different applications.

Design and Features

Imperial single deep groove ball bearings consist of an inner and outer ring with a row of steel balls in between, separated by a cage. The groove on the inner and outer rings is deeper than the radius of the balls, ensuring that the balls remain in place while allowing for smooth rotation. This deep groove design enables the bearing to handle both radial and axial loads effectively, providing stability and support in various operating conditions.

Load Handling and Performance

One of the key attributes of imperial single deep groove ball bearings is their ability to handle significant radial loads and moderate axial loads. This makes them suitable for applications where both types of loads are present, such as in electric motors, pumps, and gearboxes. The design allows for high-speed operation, making these bearings ideal for applications requiring efficient and reliable performance at elevated speeds.

Maintenance and Longevity

Proper lubrication and maintenance are essential for the longevity and performance of imperial single deep groove ball bearings. Regular inspection and lubrication help reduce friction and wear, extending the life of the bearings and preventing premature failure. Additionally, seals and shields can be used to protect the bearings from contamination, further enhancing their durability and performance.

The Advantages of High Speed Linear Bearings

High speed linear bearings are critical components in modern mechanical systems, offering numerous advantages that enhance performance and efficiency. These bearings are designed to provide smooth linear motion with minimal friction, making them ideal for applications requiring high speed and precision.

Precision and Accuracy

One of the primary advantages of high speed linear bearings is their ability to provide precise and accurate linear motion. The design of these bearings reduce friction and ensures smooth movement, which is essential in applications where accuracy is paramount. For example, in CNC machines and precision instruments, high speed linear bearings enable precise positioning and movement, resulting in high-quality outputs and improved performance.

Load Capacity and Durability

High speed linear bearings are capable of handling significant loads while maintaining their performance at high speeds. The load-carrying capacity of these bearings ensures that they can support heavy components and maintain smooth operation under stress. This makes them suitable for applications in industries such as manufacturing, where heavy machinery and equipment rely on durable and reliable bearings to function efficiently.

Reduced Friction and Wear

The design of high speed linear bearings focuses on reduce friction, which in turn reduces wear and tear on the components. This reduction in friction bring about lower energy consumption and less heat generation, contributing to the overall efficiency of the system. By reducing wear, these bearings also extend the service life of the machinery, reducing maintenance costs and downtime.

Versatility and Application Range

High speed linear bearings are versatile and can be used in a wide range of applications. They are commonly found in industrial automation, robotics, and medical devices, where precise and smooth linear motion is crucial. In industrial automation, these bearings enable fast and accurate movement of components, increasing production speed and efficiency. In robotics, they contribute to the precise control of robotic arms and other moving parts, enhancing the overall performance of the robot. In medical devices, high speed linear bearings ensure smooth and precise operation, which is essential for sensitive and delicate procedures.

Easy Maintenance

Maintenance of high speed linear bearings is relatively straightforward, contributing to their overall cost-effectiveness. Regular lubrication and inspection are typically sufficient to keep these bearings in condition. Some designs also feature seals and shields to protect against contaminants, further reducing the need for frequent maintenance and ensuring reliable performance over time.

English

English русский

русский Español

Español