-

Wheel Hub Bearings

Wheel Hub Bearings -

Wheel Hub Bearings

Wheel Hub BearingsDAC387436 DAC458045 Hub Deep Groove Ball Car Wheel Bearing

-

Spherical Bearings

Spherical BearingsFL204 FL205 FL206 Stainless Steel Pillow Block Bearing

-

Spherical Bearings

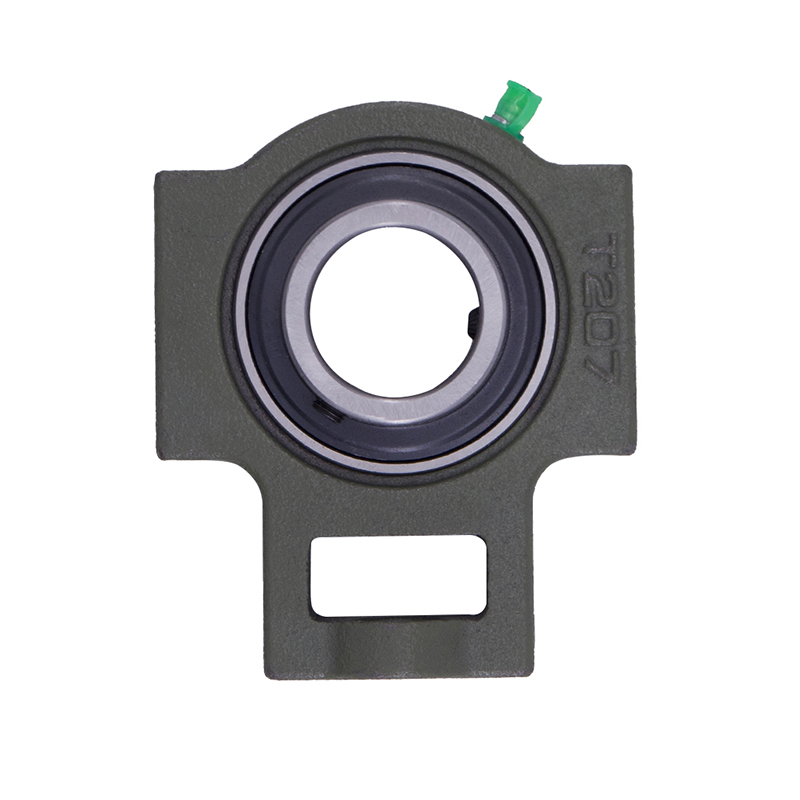

Spherical BearingsT204 T207 UC204 High Speed Insert Pillow Block Bearing

-

Spherical Bearings

Spherical BearingsFC204 F210 Auto Wheels Bike Pillow Block Bearing

-

Spherical Bearings

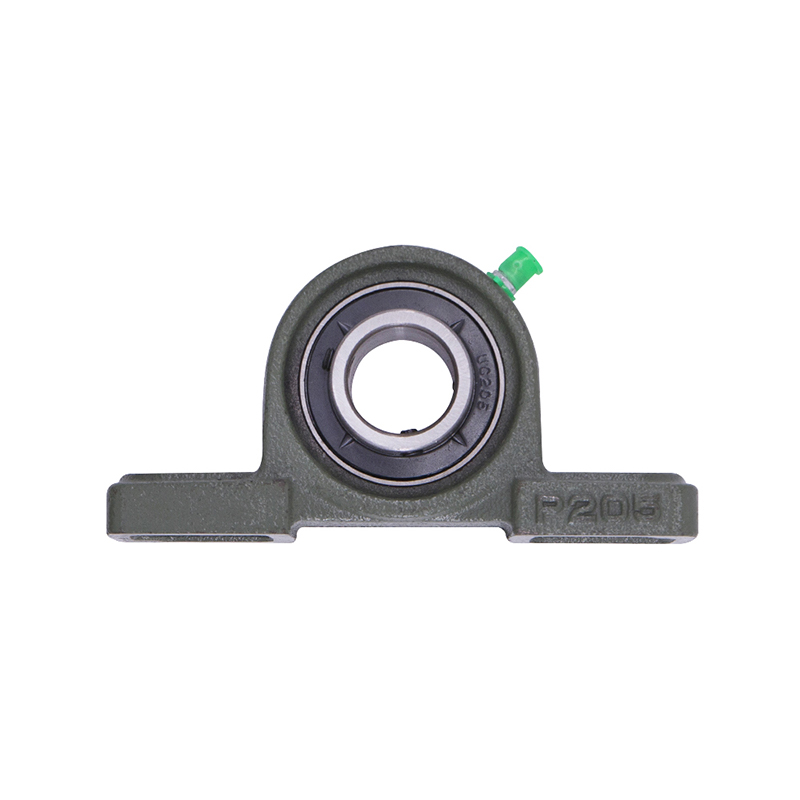

Spherical BearingsP207 206 205 203 High Precision Wheel Pillow Block Bearing

-

Thrust Roller Bearings

Thrust Roller BearingsS51100 S51107 S51109 Car Wheel Plain Thrust Ball Bearing

-

Thrust Roller Bearings

Thrust Roller Bearings51110 51107 51104 51206 High Speed Plain Thrust Ball Bearing

Sealing and Protection Types of Small Single Tapered Roller Bearings

Industry news-Small Single Tapered Roller Bearings are essential components in various mechanical applications due to their ability to handle both radial and axial loads efficiently. Their design and functionality make them suitable for use in many industries, including automotive, aerospace, and industrial machinery. One of the critical aspects that ensure the longevity and reliability of Small Single Tapered Roller Bearings is their sealing and protection.

Importance of Sealing and Protection

The primary purpose of sealing and protection in Small Single Tapered Roller Bearings is to prevent contaminants such as dust, dirt, water, and other debris from entering the bearing. Contaminants can cause significant damage to the bearing by increasing friction, bringing about wear and corrosion. Proper sealing and protection also help retain lubrication within the bearing, ensuring smooth operation and reducing the frequency of maintenance.

Types of Seals for Small Single Tapered Roller Bearings

There are several types of seals used in Small Single Tapered Roller Bearings, each offering different levels of protection depending on the application requirements. The common types include contact seals, non-contact seals, and hybrid seals.

Contact Seals

Contact seals, also known as lip seals or radial seals, provide good protection against contaminants by maintaining direct contact with the bearing surfaces. These seals are typically made from elastomeric materials such as rubber or synthetic polymers, which offer flexibility and durability. The main advantage of contact seals is their ability to provide a tight seal, effectively preventing contaminants from entering the bearing.

However, contact seals can generate friction and heat due to their direct contact with the bearing surfaces. This friction can slightly reduce the bearing's efficiency and increase the operating temperature. Despite this, contact seals are widely used in applications where protection against contaminants is required, such as in off-road vehicles, agricultural machinery, and construction equipment.

Non-Contact Seals

Non-contact seals, also known as labyrinth seals or gap seals, do not make direct contact with the bearing surfaces. Instead, they create a complex path for contaminants to navigate, effectively reducing the likelihood of ingress. These seals are typically made from metal or rigid plastic materials and are designed to provide minimal friction, resulting in higher efficiency and lower operating temperatures.

The main advantage of non-contact seals is their ability to operate at high speeds without generating significant heat. However, they may not offer the same level of protection against fine contaminants as contact seals. Non-contact seals are commonly used in high-speed applications, such as in electric motors, fans, and turbines, where low friction and high efficiency are critical.

Hybrid Seals

Hybrid seals combine the advantages of both contact and non-contact seals, offering a balance between protection and efficiency. These seals typically feature a primary contact seal for protection and a secondary non-contact seal to reduce friction and heat generation. Hybrid seals are ideal for applications where both high protection and low friction are required, such as in automotive wheel bearings and industrial gearboxes.

Protection Types for Small Single Tapered Roller Bearings

In addition to seals, Small Single Tapered Roller Bearings can be equipped with various protective features to enhance their performance and durability. These protective features include shields, covers, and special coatings.

Shields

Shields are metal discs that cover the bearing openings, providing a barrier against larger contaminants while allowing for some ventilation. Unlike seals, shields do not make contact with the bearing surfaces, resulting in no additional friction or heat generation. Shields are suitable for applications where moderate protection is sufficient and where low maintenance and high efficiency are desired.

English

English русский

русский Español

Español